- Home

- About

- Products

- Product Testing

- Application

- Services

- Information

- Contact

Views: 6887 Author: Site Editor Publish Time: 2020-05-26 Origin: Site

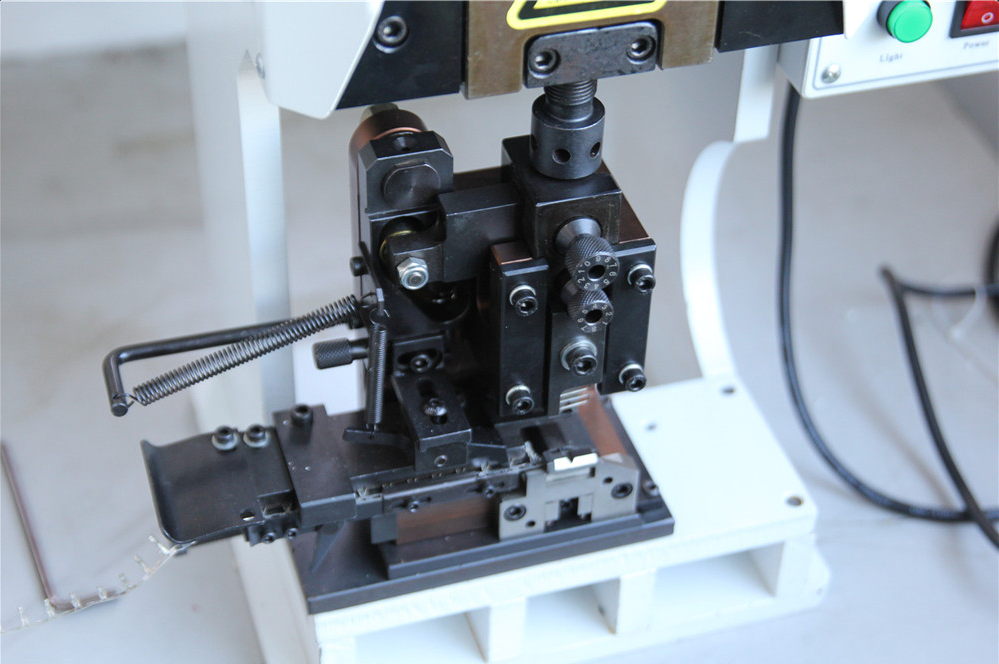

Choosing high-quality equipment will not only make the company profit, save manpower, but also improve the corporate image and enjoy a good reputation in the industry. Fully automatic terminal machine is also known as automatic peeling and crimping machine, it is grafted together with feeding, cutting and other functions. Among them, the wire feeder of the terminal machine is used with the automatic terminal machine, and wire stripping machine pay-off rack is suitable for fully automatic computer wire stripping machine. The wire stripping frame is suitable for the wire stripping machine. It mainly sends the wire to the wire stripping machine for more stable and fast wire feeding. Therefore, choosing a high-quality fully automatic terminal machine is the key to your success.

The operation process of the automatic terminal machine is relatively simple. Because it is a fully automatic method, it saves labor more. First, you must turn on the power switch of the terminal machine , and after the power indicator lights, start to use it. The support tool must be compared with the blade by hand. The knife comparison is correct. After the knife is completed, the manual test must be used. The terminal equipment needs to be hit. Use the hexagonal wrench to adjust the feed plate so that the terminal can easily pass. The terminal operator must check whether there are plastic bags, hanging, etc. during the production process, and a terminal tensile must be tested every 1 hour.

In order to ensure the perfection of functions, special attention should be paid to the design of automatic terminal machines. With the social-economic development, competition between the same industry is particularly prominent. To improve the competitiveness of automatic terminal machines, it is necessary to improve the design structure and follow certain design principles. Reasonable structural design brings customers a more advantageous price-performance ratio and a more human-friendly interface design, which makes technicians' operations more convenient and fast. Smoother program design makes the automatic terminal machine work more efficiently, faster and better.

During the use of mechanical equipment, the most worrying issues are safety and stability. Therefore, when designing the internal structure, we must pay attention to the assembly of each component. The structural design should also conform to the principles of mechanics to maintain the entire structure stability. In the external design, it is necessary to consider the contact and beauty, take good measures for leakage protection, and also reduce the external corner design to ensure its safe use. The beauty of the automatic terminal machine is also very important.

During the operation of the automatic terminal machine, if the machine is abnormal, turn off the power, and ask the maintenance personnel to inspect and debug in time. During the operation, even the power of the machine is cut off, it is strictly forbidden to enter the punching area with fingers or any part of the body to avoid accidents.

Choosing a high-quality fully automatic terminal machine can make better terminal and terminal connector, which is the key to your success.