- Home

- About

- Products

- Product Testing

- Application

- Services

- Information

- Contact

Views: 1218 Author: Site Editor Publish Time: 2020-07-10 Origin: Site

After the end of the Second World War in 1946, the United States formulated a "aluminum-based copper" technology policy in response to the shortage of copper resources. However, in the 1960s, the performance defects of aluminum cables caused increasingly serious hidden safety problems. With the development of alloy smelting technology, aluminum alloys have very good characteristics, such as greater strength and higher ductility. Let's take a look at the current status lag of domestic and foreign aluminum alloy cable connection technology.

In 1970, in order to cooperate with and support wire and cable manufacturers, connector companies and electrical laboratories, they actively carried out research and development of connector technology for AA-8000 series aluminum alloy conductors. The application of American alloy cables took only two years from the invention of product technology to the improvement of related mating connector technology and products.

In the 1980s, the US wire and cable industry gained new development. Regarding product standards, procedures and technical specifications, electrical grade 8000 series aluminum alloy conductors have been cited. AA-8000 series aluminum alloys are officially used as building wire and cable and power cable conductors, and are rapidly promoted around the world.

In the research and development of wire and cable products in China, the development of wire and cable installation and laying hardware always lags behind the progress of wire and cable development. Nowadays, the development of aluminum alloy cables also has the big problem of lagging in the technology of supporting hardware (connecting accessories). This severely restricts the popularization and application of aluminum alloy cables.

In recent years, domestic enterprises have also invested in the aluminum alloy manufacturing industry one after another, and China has also started to formulate aluminum alloy cable product standards and installation technical standards in a timely manner, so that aluminum alloy cables have developed rapidly in China. However, the domestic promotion and application of aluminum alloy cables do not have matching connectors. Such a connection solution cannot guarantee the safe application of aluminum alloy cables, which will leave hidden dangers.

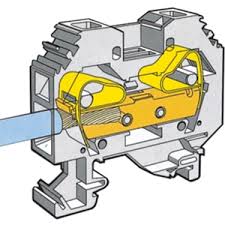

Recently, UMI Electric, which was informed of the product strategy at the end of 2012 and gradually shifted to the domestic market, took the lead in successfully developing the special connection terminal for aluminum alloy cables, making the company the first to have a complete set of technology and product solutions in the industry. There is no special matching connector problem for alloy cable application. This is a responsible enterprise's approach, it is the right direction, and has made great contributions to the sustainable development of the aluminum alloy cable industry.

We believe that the alloy cable connection technology will have a good development and a prosperous market in the future. If you have any procurement requirements for terminal connector, cable connector, electrical wire, electrical cable, please contact us in time.